High Speed Steels

Products

High Speed Steels

The characteristic properties of all high-speed steel grades include:

- High working hardness

- High wear resistance

- Excellent toughness

- Compressive strength

- High retention of hardness and red hardness

- Strength to prevent breakage on the cutting edge

Matrix-type high speed steel (QHZ)

The QHZ is a matrix-type high speed steel. QHZ contributes to increased productivity and reduction of manufacturing cost by dramatic improvement of dies service life.

Chemical Composition

| C | Si | Mn | Cr | Mo | V |

| PATENTED | |||||

Standards

| QHZ | YXR33 |

Features of QHZ

High strength and unrivaled toughness are both achieved by reducing massive carbides in steels.

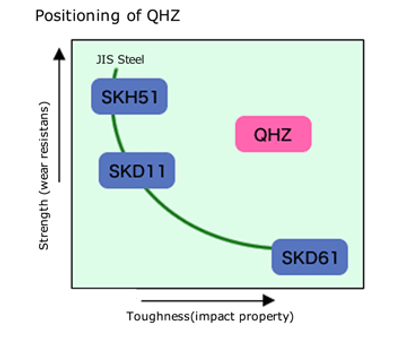

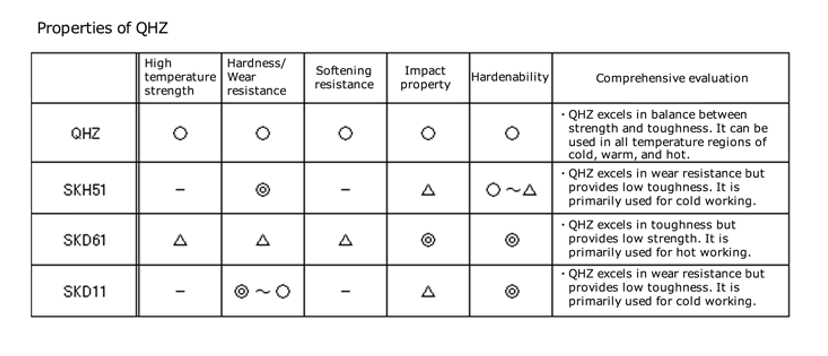

• QHZ is a matrix-type high speed steel that combines high strength equivalent to SKH51 and excellent toughness by improving microstructure and the distribution of carbides.

• Due to superior toughness and high temperature strength combined with much higher hardness than conventional hot working die steel, QHZ is suitable for cold, warm, and hot forming.

Applications

- Cold forging dies

- Hot/Warm forging dies

- Sleeves for Aluminium dies casting, etc.

Merit of QHZ

Long service life even under severe application environment

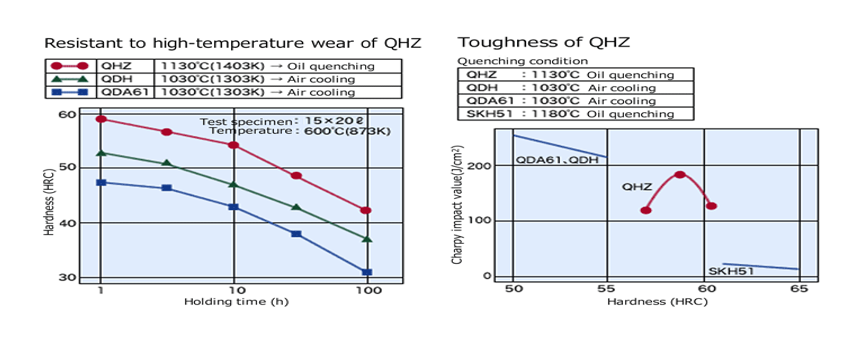

QHZ is resistant to high-temperature ware, deformation, cracking and chipping, etc; It is expected to increase the service life of dies even under severe application environment.

Positioning and Properties of QHZ

| Chemical Composition | Application | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Grade | C | Si | Mn | P | S | Cr | Mo | V | Ni | Cu | W | Co | |

| M35 | 0.92 | 0.32 | 0.28 | 0.025 | <0.001 | 3.91 | 4.90 | 1.82 | 0.18 | 0.12 | 6.12 | 4.67 | As M2, Hobs, Drill reamers, Milling cutters and Forging Dies, Cold Forming Tools etc. |

| M42 | 1.09 | 0.47 | 0.30 | 0.020 | <0.010 | 3.77 | 9.29 | 1.21 | 0.3 | 0.21 | 1.51 | 7.94 | Taps, Reamers, Broaching tools, Twist drills. |

| T1 | 0.78 | 0.33 | 0.29 | 0.018 | - | 3.98 | - | 1.13 | - | - | 18.15 | - | Turning, planing and slotting tools, tapes, twist drills, threading dies, profile cutting tools, broaching tools, reamers. |

| ASP2023 | 1.28 | 0.61 | 0.30 | 0.030 | 0.020 | 4.00 | 4.88 | 2.98 | 0.21 | 0.14 | 6.11 | 0.24 | Gear cutting tools, Cold work, Broaches, Rolls, Taps, Knives, Plastic injection etc. |

| ASP2030 | 1.25 | 0.29 | 0.27 | 0.020 | 0.020 | 4.10 | 5.00 | 3.00 | 0.21 | 0.090 | 6.30 | 8.40 | Standard grade/good balance of properties, |

| ASP2052 | 1.59 | 0.29 | 0.27 | 0.025 | 0.23 | 4.95 | 1.94 | 4.75 | 0.21 | 0.12 | 10.48 | 8.04 | Machining (Grinding, Turning, Milling), Polishing, Plastic Forming. |

| ASP2060 | 2.20 | 0.36 | 0.32 | 0.026 | 0.024 | 4.12 | 6.82 | 6.39 | 0.20 | 0.14 | 6.48 | 10.36 | Good wear resistance and highest hardness of 70 HRC. |