| C | Si | Mn | P | S | Cr | Mo | V | Ni+CU |

|---|

| 0.5 | 0.8 | 0.7 | 0.03 | 0.03 | 5 | 1.6 | 0.3 | 0.6 |

Applications

- For Tools with Good Resistance to Impact and Softening

- Forging Dies

- Punches

- Chisels

- Hammer

- Hot Heading Dies

- Gripper Dies

- Shear Blades

Properties

- High Impact Resistance

- Excellent Toughness at high Strength levels

- Good Wear Resistance

- High Hardenability & Softening Resistance

- Annealing—Heating slowly and uniformly to 815~845℃, furnace cooling to 510℃ at a rate 8~15℃/hr. Hardness max. HB 229

- Stress Relieving — Warming to 650℃, furnace cooling.

- Hardening—

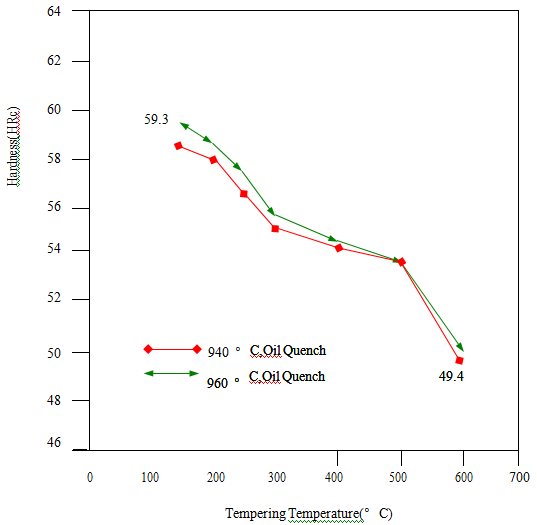

Preheating: Warming to approx. 650~700℃, holding 20 minutes per 25 mm.

Austenitizing: Heating to approx. 925~960℃, holding 20 minutes per 25 mm.

Quenchant: By oil - Tempering—150~200℃, holding 30 minutes per 25 mm. Air-cooling.

Hardness min. HRC 56