O1

Description

This grade gives higher hardness values than THYRODUR 2842 and a better wear-resistance owing to tungstene presence, whereas preserving a good toughness.

Chemical Composition

| C | Si | Mn | Cr | V | W |

|---|---|---|---|---|---|

| 1 | 0.25 | 1.05 | 0.55 | 0.15 | 0.58 |

Standards

| AISI O-1 | 1.2510 | 100MnCrW4 | A681 | 9CrWMn | SKS3 | AFNOR 2212 |

Properties

| Thermal Conductivity at °C | 20 | 350 | 700 |

|---|---|---|---|

| W/(m • K) | 33.8 | 32.2 | 31 |

Applications

- Blanking and stamping dies for cutting sheets

- Threading tools

- Drills

- Broaches

- Gauges

- Measuring tools

- Plastic moulds

- Shear blades

- Guide rails

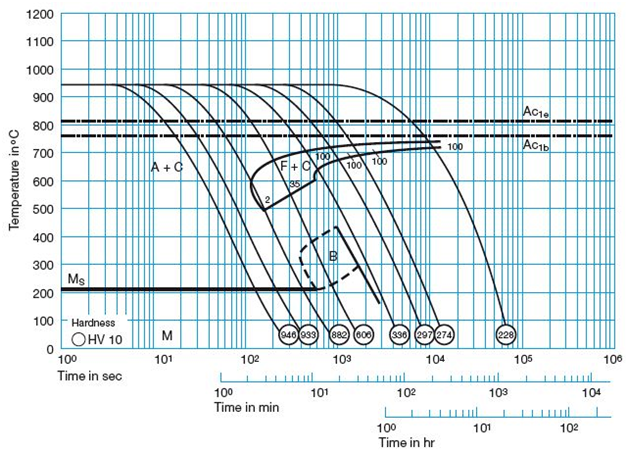

Heat Treatment

| Soft annealing °C | Cooling | Hardness HB |

|---|---|---|

| 750 - 780 | Furnace | max. 230 |

| Stress-relief annealing °C | Cooling |

|---|---|

| approx. 650 | Furnace |

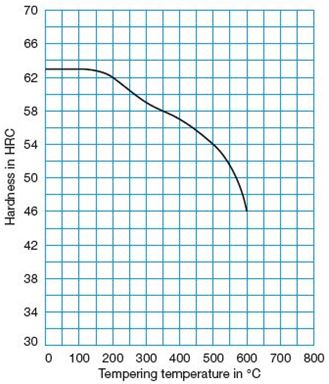

| Hardening °C | Quenching | Hardness after quenching HRC |

|---|---|---|

| 780 - 820 | Air, oil or saltbath, 180-220 °C | 65 |

| Tempering °C after quenching | 100 | 200 | 300 | 400 |

|---|---|---|---|---|

| HRC | 63 | 62 | 58 | 53.5 |