AISI D-3

Description

This tool steel specification is noted for its resistance to abrasion. It offers excellent dimensional stability in hardening. After heat treatment the tool steel is hard, durable, dense, and is immune from sinking in use. It offers a measure of corrosion resistance when polished. In general, the applications of 1.2080 tool steel resemble those of 1.2379 but it should be remembered that 1.2080 has better wear resistance of the two steels and is preferred for such items as shear blades. Owing to its higher wear resistance, 1.2080 tool steel is slightly more difficult to grind than 1.2379.

Chemical Composition

| C | Si | Mn | Cr |

|---|---|---|---|

| 2.1 | 0.32 | 0.29 | 11.5 |

Standards

| AISI D-3 | 1.2080 | X210Cr12 | SKD-1 | Cr12 | NCll |

Properties

Steel with 12% chromium, wear-resistant with high cutting performance. The use fo this grade is developing towards THYRODUR 2436.

Applications

- High efficiency blanking tools

- Deburring and splitting tools

- Tools for cutting paper and plastic materials

- Dies and balls for drawing

- Thread rolling tools

- Straight and round shears

- Deep-drawing tools

- Tools for working wood

- Tools for pressing abrasive materials such as porcelain

- Slides and moulds for plastic materials.

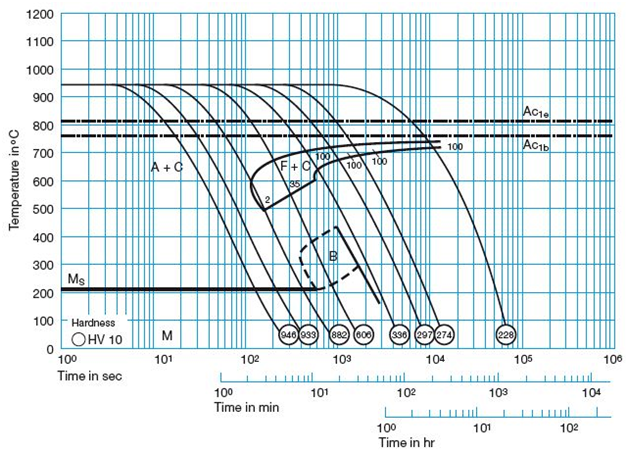

| Hardening from | 950-980°C |

|---|---|

| In | Oil at 80°C, vacuum or hot bath at 500-500°C Air (up to 30 mm thickness) |