About Us

Stores Supply (India) Agency

Our company has been into import and marketing of Tool and Die Steel for 65+ years and we are one of the oldest (and most trustworthy) stockeists in India. We have vast experience in marketing Tool Steels of some of the most reputed brand names in the world like Bohler International Gmbh (Austria), Deutsche Edelstahlwerke (Germany), Gloria Materials Technology Corporation (Taiwan), Sanyo Special Steel Co. Ltd. (Japan), Bropol Co. Ltd. (Poland), (Dongbei Special Steel Group (China), Mahindra Sanyo Special Steel Private Limited, Visvesvaraya Iron and Steel Ltd.).

We are the oldest company in our field

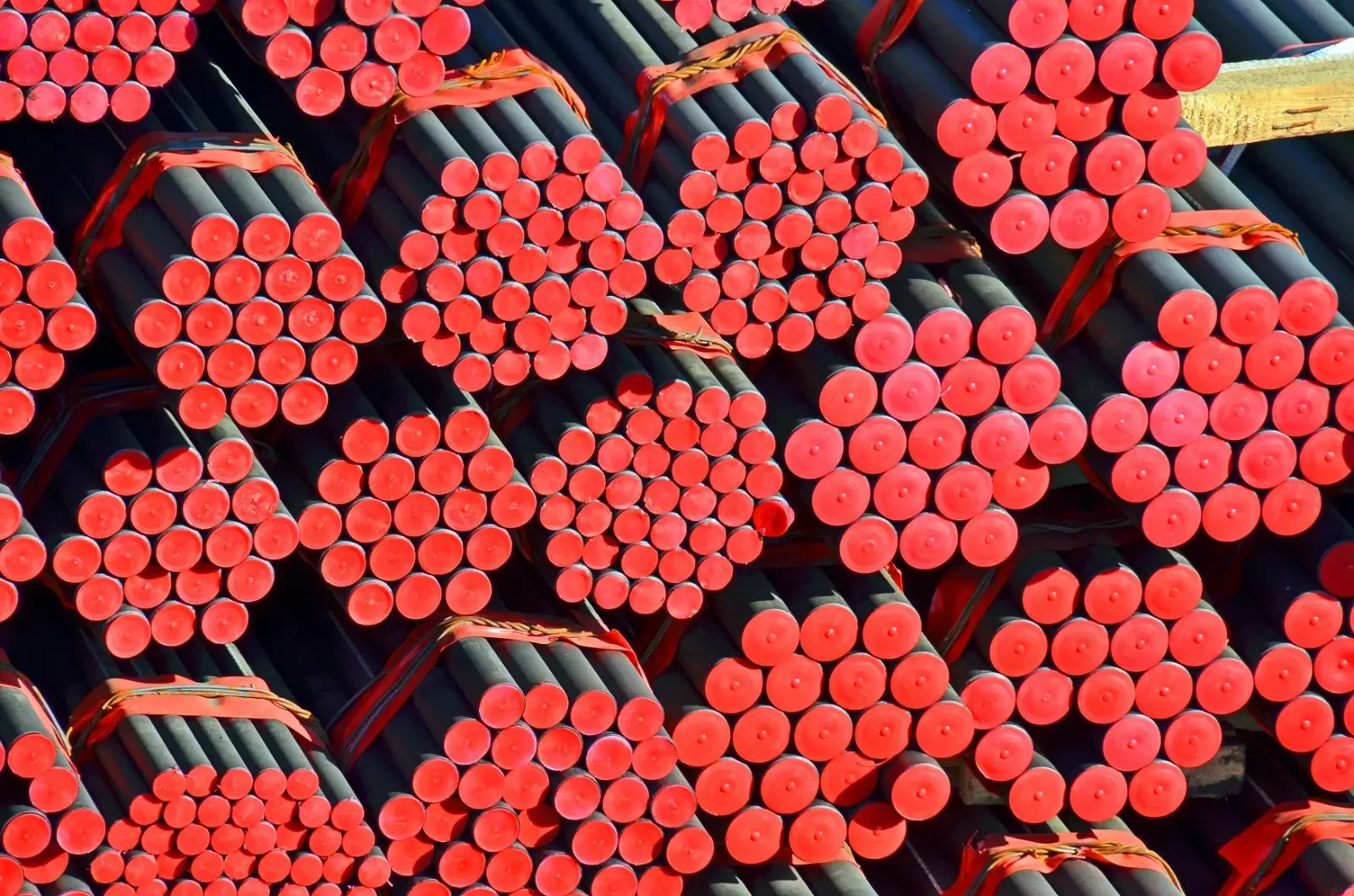

We have the largest stock with sizes ranging from 4 mm dia to 1200 mm dia

We have the largest variety of grades in India

We are associated with the best mills in the world

Years Of Experience

Products We Deal In

We also deal in steels produced through the Powder Metallurgy route which despite being very expensive is highly cost effective

Hot Work Steels

Plastic Moulding Steels

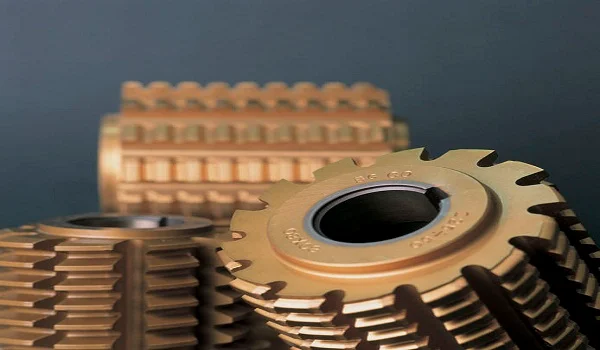

High Speed Steels

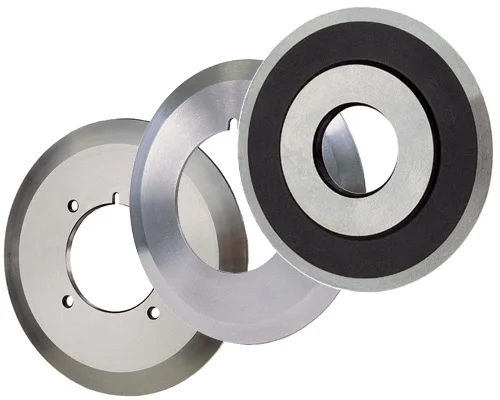

Cold Work Steels

Aerospace Steels

GET A QUOTE

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

We will get back to you within 24 hours, or you can call us everyday 10:00 AM – 7:00 PM

Get In Touch

Complete control over products allows us to ensure our customers receive the best quality prices and service